New Transportation Staff

Project Manager, Jacob Isenburg

About this project:

This project utilized the unique technique and materials of galvanized structural steel and galvanized rebar in the concrete bridge deck and approach slabs.

A fabrication restriction for galvanizing structural steel is the limited tank length that galvanizers have available to dip longer steel beams into for galvanizing. HWC worked with the American Galvanizers Association to address these fabrication limitations and included optional splice details in the structural steel drawings to accommodate as many potential bidders as possible to optimize the costs of fabrication, galvanizing, shipping, and installation.

Indiana counties have limited budgets for bridges and maximizing these budgets are key to the sustainability of their bridge assets. The previous bridge was built in 1930 and reconstructed in 1967. The galvanized steel and rebar are designed to achieve the target 100-year bridge service life with limited maintenance requirements. This project represents White County’s second project using galvanized structural steel and galvanized rebar. White County has made galvanized rebar standard use for their major bridge projects.

The Soy Transportation Coalition (https://www.soytransportation.org/) has recognized galvanized structural steel as 1 of the top 20 innovative techniques to making existing tax dollars stretch further.

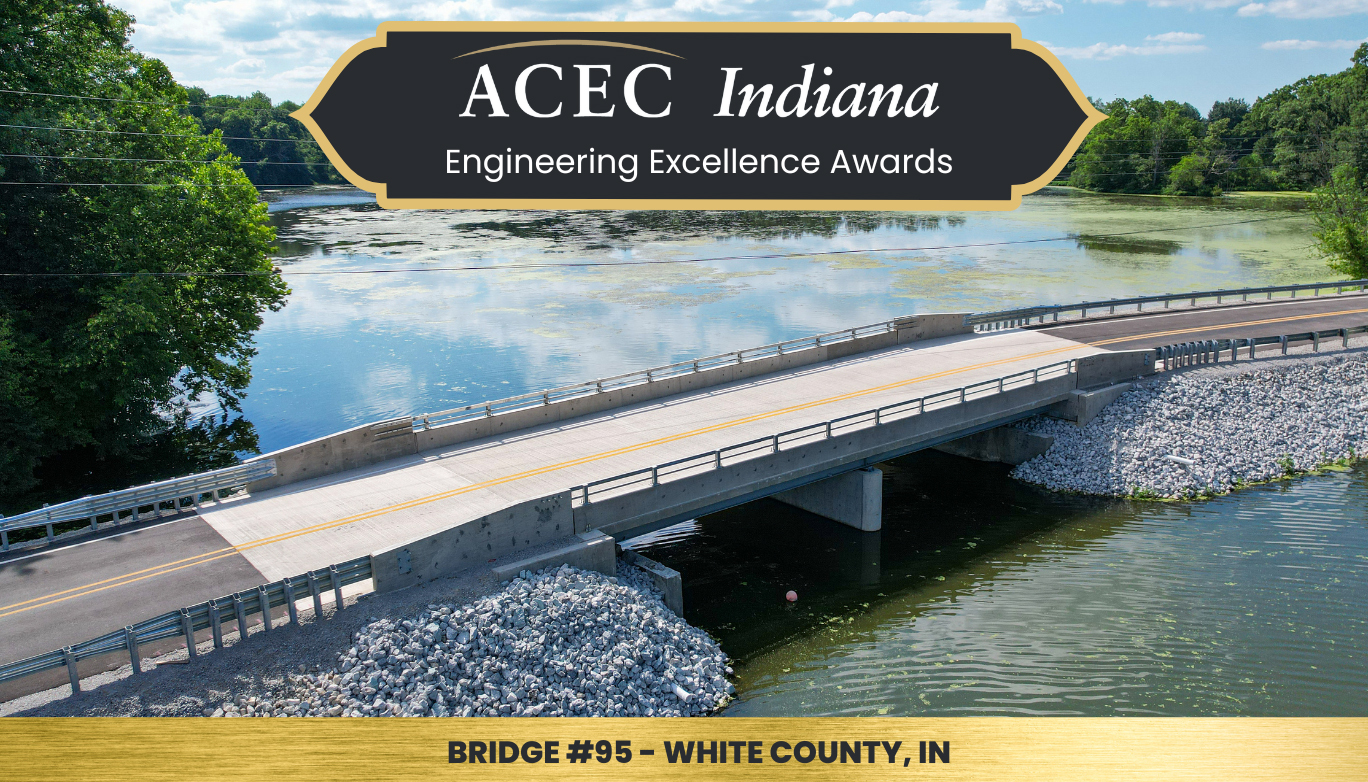

This section of CR 300 East is one of the main north-south corridors in White County and serves as a main route around Lake Shafer for both commuting and recreational traffic. The construction time window was set during fall, winter, and spring to avoid the busy season for the local economy. This was set intentionally to minimize any economic impact to local businesses. The constructed project enhances the safety of the corridor by improving the road geometry, sight distances, roadway drainage, among other factors.

The use of galvanized steel will provide economical life-cycle cost savings for bridge maintenance. The galvanized coating was designed to not require any maintenance to the steel for the 100-year service life and is 100% recyclable.

The project successfully navigated the complex challenge of balancing costs, impacts to environment and residents, and providing safe roadway. The prioritization of any one of these variables over the others would have resulted in detrimental impacts. The finished project was one that brought all of these variables into harmonious balance.

The use of galvanized steel will provide economical life-cycle cost savings for bridge maintenance. The galvanized coating was designed to not require any maintenance to the steel for the 100-year service life and is 100% recyclable.

HWC is proud and thankful to have worked on this project for White County and to have received this special recognition from ACEC.

Recent Comments